Rubbers are elastomers that are composed of high polymers, compounding various synthetic rubbers, carbon black, sulfur, accelerant, and auxiliary to proceed different vulcanization systems to make molecules process cross-linking. That improves rubber products' elasticity, wear resistance, toughness, chemical resistance, solvent resistance, and acid/alkali resistance. The major production processes which LeeKuma does are extrusion and molding: temperature control extrusion machine, compression molding machine, and injection molding machine, which can produce continuous-length rubber hoses and strips, and rubber molding parts with precision.

Produce continuous hoses and strips to deliver liquid, air, and oil, and fit in irregular assembling parts.

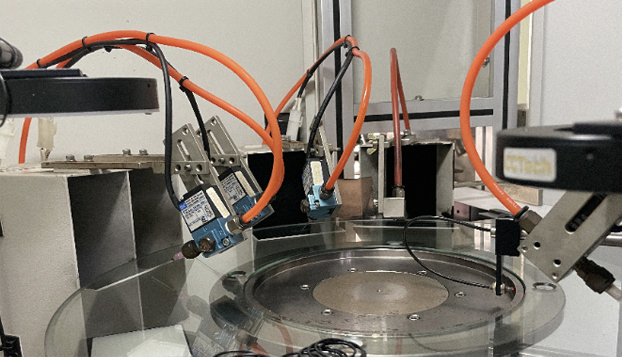

Put rubber into tooling to produce rubber molding parts, injection parts, and rubber parts with metal by rubber compression molding machine or injection molding machine. The characteristics of molding parts are complex structure, and precise dimensions which can be assembled into machine perfectly; rubber metal bonded parts enhance stiffness, and absorb vibration.