- Home

- Certification

- Certification

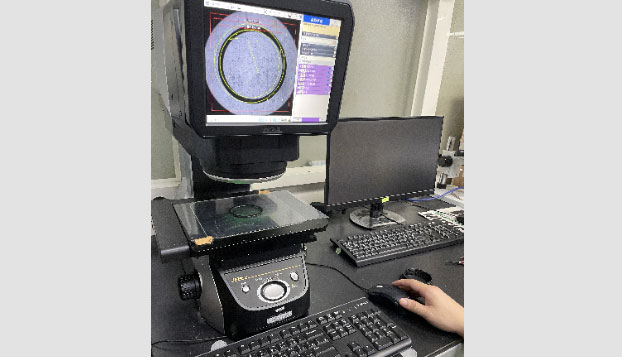

Rubber parts are used in various industries. According to different requirements from different industries, rubber parts need to be oil-resistant, heat-resistant, wear-resistant, ozone-resistant, low-temperature-resistant, acid/alkali resistant, etc. We use different formulas to adjust the properties, and test the material with precision instruments in specific situation simulations to ensure the rubber parts be suitable, durable, and stable. Our RD department is dedicated to testing rubber formula properties, and also works with third-party inspection institutions to ensure that products meet the requirements of environmental restrictions and become a trustworthy supplier.

Rubber formulas perform properties that are evaluated through the standard test to judge the applicability and service life. We follow two major testing standards: the American Society for Testing and Materials International ( ASTM )and the Japanese Industrial Standard (JIS). The original properties include hardness, elongation, tensile strength, and specific gravity. By testing heat-resistant, oil-resistant, low-temperature-resistant, ozone-resistant, compression test, and insulation value, we compare the test value variation of hardness, elongation, tensile strength, and volume with original properties and provide our customers with stable rubber products.

Natural Rubber originates from Hevea Brasiliensis, and its excellent elasticity and resilience are applied to industry. To meet more special requirements, people refine petroleum to get synthetic rubbers.

| Rubber Material | Properties | |

|---|---|---|

| ACM | Acrylate Rubber | Oil Resistance, Heat Resistance |

| CR | Chloroprene Rubber (Neoprene) | Ozone Resistance, Weather Resistance, Chemical Resistance |

| CSM | Chlorosulfonated Polyethylene Rubber | Heat Resistance, Corrosion Resistance |

| EPDM | Ethylene-propylene Rubber | Acid and Alkali Resistance, Heat Resistance, Ozone Resistance, Solvent Resistance |

| FKM | Fluoro Elastomer (VITON) | Fuel Resistance, Acid and Alkali Resistance, Heat Resistance |

| HNBR | Highly Saturated Nitrile Rubber | Heat Resistance, Chemical Resistance |

| MQ | Silicone Rubber | Heat Resistance, Weather Resistance, Ozone Resistance |

| NBR | Nitrile Rubber | Oil Resistance, Solvent Resistance |

| NR | Natural Rubber | Wear Resistance, High Elasticity, High Tensile Strength |

| PU | Polyurethane | Oil Resistance, Wear Resistance |

Rubber

(Neoprene)

Polyethylene Rubber

Rubber

(VITON)

Nitrile Rubber

Rubber

Rubber

Rubber

Recently, international requirements become stricter, especially RoHs and Reach, which the USA and EU governments request all imported products to comply with these restrictions, and restrict the use of hazardous substances: lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), etc. In response to these environmental regulations, LeeKuma keeps improving R&D to meet the updated regulations; Besides these two restrictions, we develop a new formulary to meet Polycyclic Aromatic Hydrocarbons (PAHs) category 2, limitation of the sum of 18 hazardous substances and Phthalates, etc. to confirm the products complied with importing country requirements.

ISO 9001:2015

License No.D53214

Membership Certificate

PAHs

PAHs

Top Level Membership Certificate